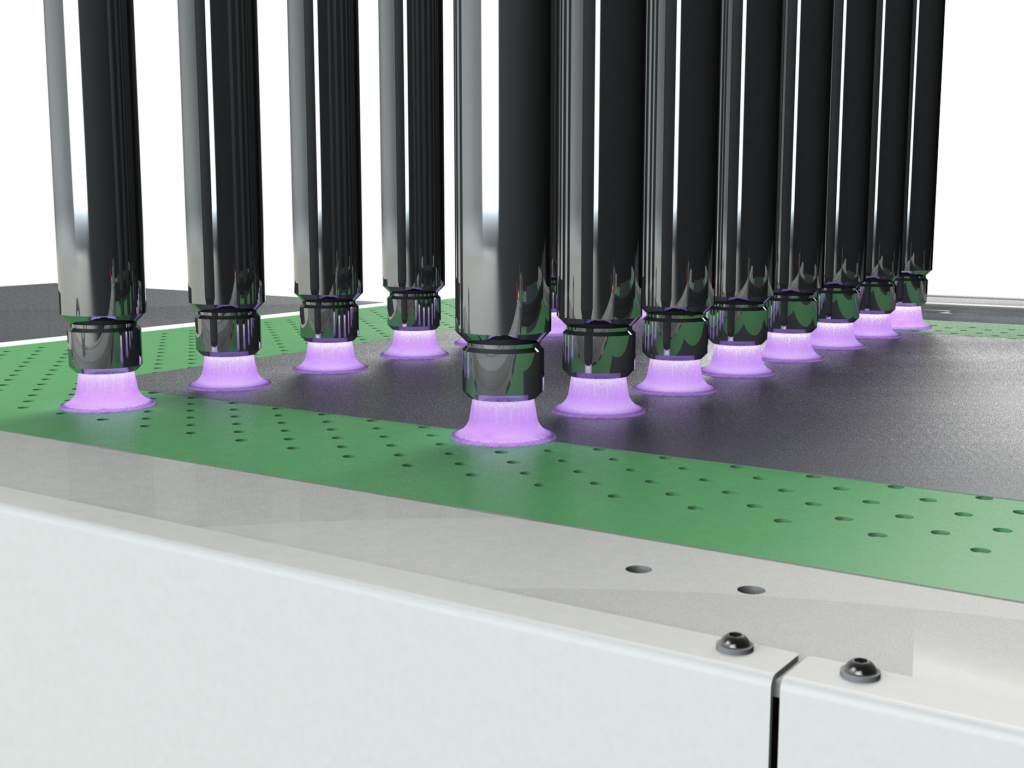

Developed in collaboration with Brasilata Labs, our plasma conveyor system enhances the surface energy of virgin metal sheets, improving the adhesion of UV coatings while eliminating the need for energy-intensive thermal ovens. The system is designed to seamlessly integrate between a standard Crabtree coating line and feeder.

Delivers full UV coating for virgin metal sheets without the need for energy-consuming oven curing.

The complete system reduces carbon emissions by up to 40% compared to solvent-based coatings.

Potentially lowers VOC emissions by up to 95%, promoting a cleaner production process.

Undergoing over 3 years of successful testing at a customer site for proven performance.

Fully belted vacuum conveyor system ensures perfect sheet flatness and even plasma coating.

Fully belted vacuum conveyor system ensures perfect sheet flatness and even plasma coating.

Sensitive crash bar stops the conveyor to prevent damage to the plasma nozzles.