Crabtree’s SMS (Sheet Management System) is our premium solution for inline sheet management and quality inspection. Designed to enhance efficiency and minimise waste, the modular system adapts to your production needs.

Choose from three specialised options:

Eject up to 20 sheets for quality inspection or small batch removal without interrupting production.

Safely reintroduce individual sheets into the production line using advanced servo drive technology.

Stack up to 200 sheets with precision using CNC side guides and a dynamic braking system, ensuring sheets remain undamaged and reusable (tested up to production speeds of 8000SPH).

Each option is retrofit-ready and easily integrates with your existing setup. Whether used independently or as part of a complete system, Crabtree’s SMS delivers unmatched reliability and precision.

Options can be used independently or as part of a complete system. With a standalone electrical system, it can be retrofitted to an existing Crabtree system or third-party equipment.

Easily integrates into existing setups with a standalone electrical system.

Dynamic braking system and CNC side guides keep sheets undamaged and fully reusable.

Overhead eject tray and reinsertion facilitates quality inspection without disrupting production.

All rejected sheets are guaranteed damage free and can be re-used as start of line waste sheets. All top inspection sheets can be safely re-inserted back into the production line.

Inline sheet stacker handles up to 200 sheets, with an extractable dolly system for safe removal.

Designed for ease of use and operational safety.

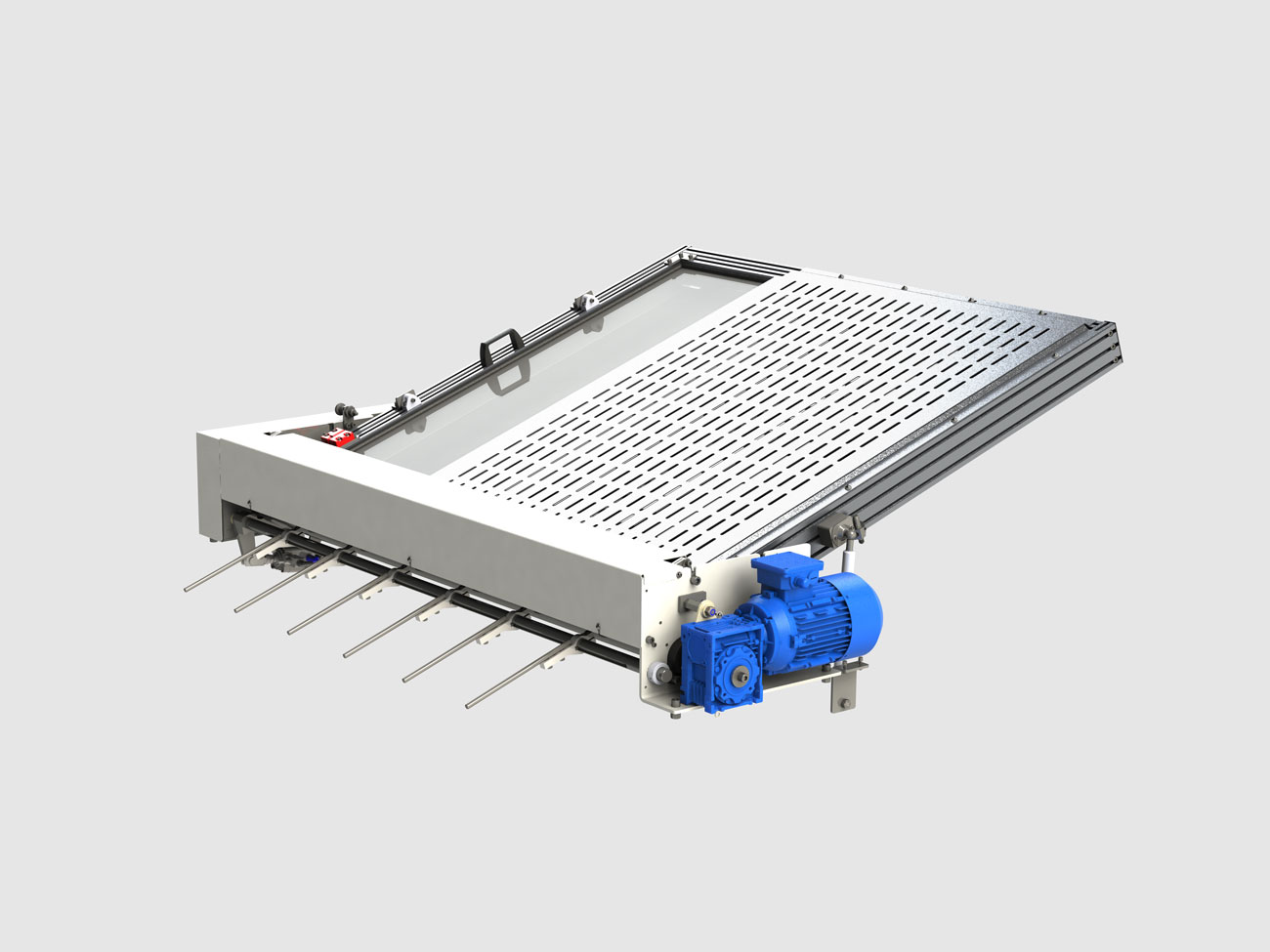

Our Basic SES offers a compact, cost-effective solution for low-speed sheet ejection and camera system rejects. Designed for simplicity and efficiency, it’s ideal for start-of-line wasters and manual inspection.

Adjustable frame mounting position allows it to suit nearly every conveyor.

Adjustable rubber cushions prevent any sheet damage during handling.

Suitable for various sheet sizes, including 510 x 1000 and 720 x 1200.

Takes up minimal space with a compact 2-meter length.

Sheets are easily removed using a sliding drawer mechanism.

Capable of ejecting up to 25 sheets at once.

Can function with a standalone electrical control system or integrate with existing Crabtree lines.

Ideal for use with start-of-line waste sheets, ensuring they are safely handled and reusable.

Designed to be as simple as possible, the bolt-on Overhead Eject Tray is the go-to for a basic eject system.

Ideal for thorough sheet inspection, ensuring accurate quality control.

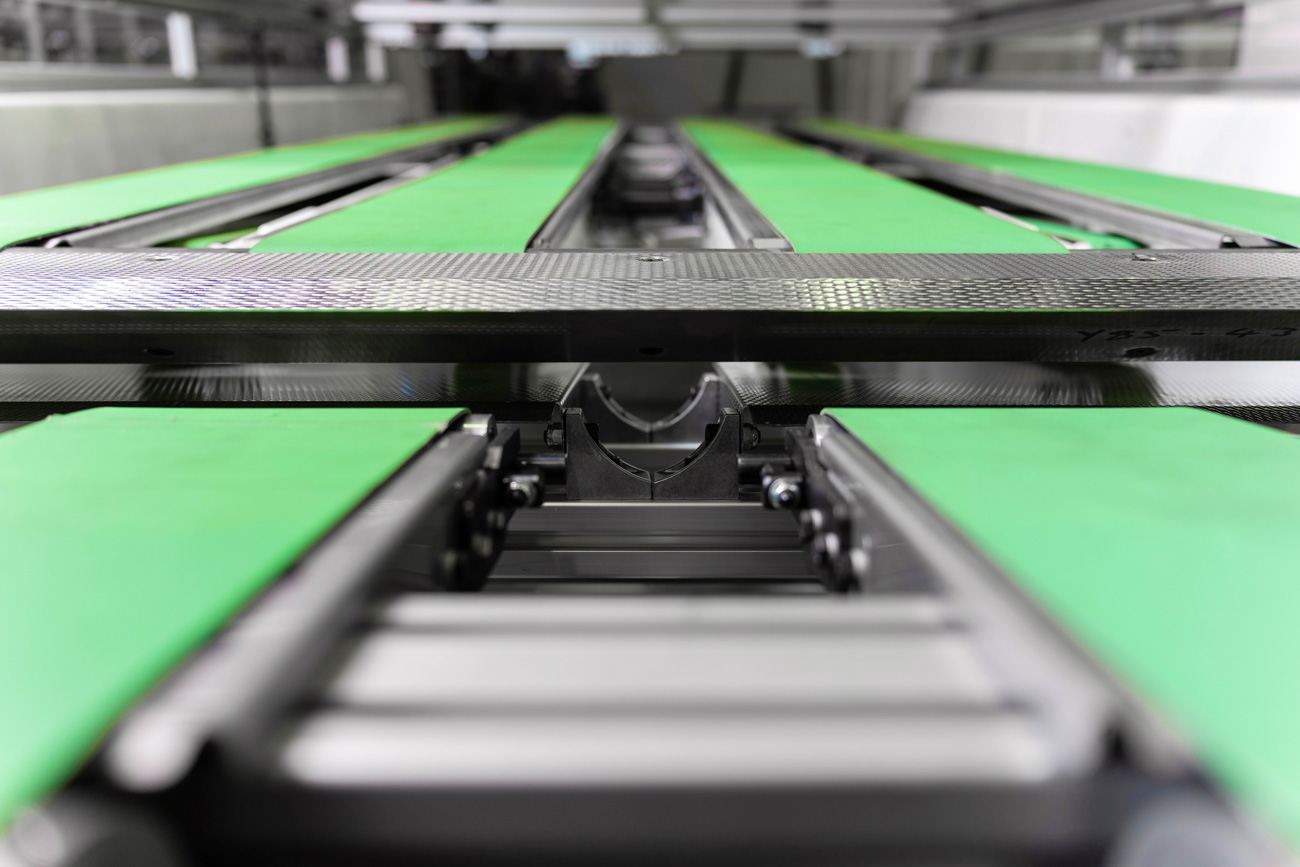

Adjustable motorised nip rollers provide controlled and consistent sheet movement.

Drop-down, adjustable fingers accommodate any conveyor belt arrangement.

Adjustable frame mounting position ensures compatibility with nearly every conveyor.

Supports all sheet sizes, including 510 x 1000 and 720 x 1200.

Rubber cushions prevent any damage to sheets during processing.

Sheets are safely removed using a sliding drawer guard mechanism.

Tray can be lifted with gas springs, providing easy access to the area below the conveyor.

Capable of ejecting up to 15 sheets at once, ensuring efficient workflow.

Features a standalone electrical control system for independent operation.

Suitable for ejecting start-of-line waste sheets at low speeds, minimising material waste.